Until now, soldering, laser welding and adhesive bonding methods have been employed for the assembly of optical fiber arrays. The soldering process is need for metallization and high heat loads and affect can affect reliability. Laser welding is regarded as having long-term stability, but it also requires metallization, gigh power lasers, and careful control of a variety of parameters. Adhesives in photonic packaging have many advantages in both cost and convenience as compared to the above-mentioned alternative conventional methods.

Currently, adhesives offer advantages in terms of mass-productivity and low-cost. The adhesives described not only perform the function of bonding, but also have the high degree of light transmittance and other properties required to form a bond most suitable from an optics point of view. They can also be cured by both heat and by light, without affecting the Fiber Amplifier. Light curing provides a number of economic advantages: rapid through-cure, low energy requirements, room temperature treatment, and non-polluting and solvent-free formulations. Inthis way, heat-sensitive materials in the assembly are not damaged during cure.

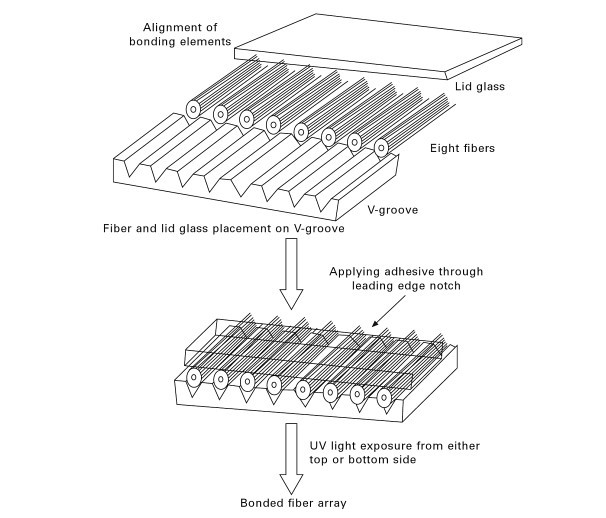

Schematic of the bonding process of eight-channel fiber array

Compatible with the components assemblly process and rates. In addition, the continuous miniaturization of photonic components and devices requires new micro and nano-dispensing techniques. One of the promising techniques for such micro-and nano-dispensing is the valve technique, which provides a dispensing system with accurate control of the dispensing needle tip, as well as improved repeatability of the deposited materials. (Related products in: Fiber Optic Splitter Box)

The curing process of the adhesive is an important factor in determining the performance of the component. Traditional thermal curing may not be suitable for adhesive curing in photonic applications. Most optical adhesives are photosensitive and require a certain type of light-source for radiation curing. Others are moisture-sensitive and may require a particular level of humidity for curing. Some adhesives can be cured in few seconds and others may require several days to achieve a full cure. They may be curable at room temperature or may require an elevated temperature. Sometimes there is a meed to compromise between the cure schedules of cure time and temperature. However, the final properties of the cured adhesive often depend upon the details of the curing process and schedule.