With the ever-increasing demands for high-density backbone cabling. MTP solutions have enjoyed widespread popularity. In this post, we will have an exploration of two MTP solutions: MTP cable and MTP cassette. For those who are unfamiliar with this term, it’s necessary for us to get started from its basics.

Background Information on MTP

In this part, you are required to acquire three terms: MTP, MPO, and polarity.

MPO stands for “multi-fiber push on” connector. Usually, it refers to a type of a multiple fiber core connector, defined by IEC-61754-7 (common standard) and the U.S. TIA-604-5 Standard.

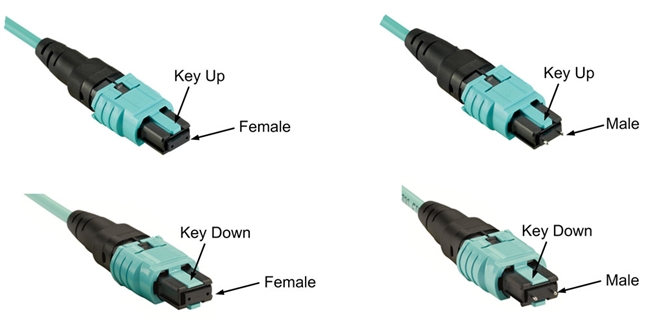

MTP is the short for “multi-fiber termination push-on” connector, which is the latest generation of MPO connector developed by US Conec. Fully compliant with the MPO standards, the multi-fiber termination push-on connector is considered as MPO fiber connector. For multi-fiber termination push-on or multi-fiber push on connector, they can both accommodate 8 to 24 fibers, which are the perfect choices for the 40G/100G network. Multi-fiber termination push-on or multi-fiber push on connector is available in a female version (without pins), or a male version (with pins) as shown in figure 1. The pins ensure the exact alignment of the fronts of the connectors, which protects the interfaces of the connectors from being offset.

Figure 1: MTP Connectors

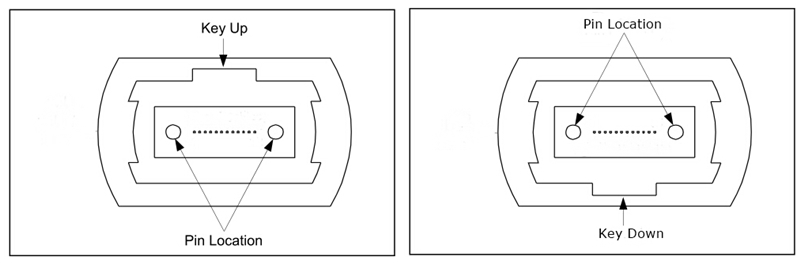

Also, there are guide grooves (keys) on the top side of the factory terminated multi-fiber termination push-on connectors, which ensure that the adapter holds the connector with the correct ends aligned with each other. According to the key, the multi-fiber termination push-on connector comes with two types. One is “key-up to key-down”, which means the key is up on the one side and down on the other. The two connectors are connected turned 180°in relation to each other. The other one is “key-up to key-up”, which means both keys are up. The two connectors are connected while in the same position in relation to each other.

Figure 2: Multi-fiber Termination Push-on Connector Structure

In any installation, it is important to ensure that the optical transmitter at one end is connected to the optical receiver at the other. This matching of the transmitting signal (Tx) to the receiving equipment (Rx) at both ends of the fiber optic link is referred to as polarity.

MTP Solutions

For multi-fiber termination push-on solutions, there are two frequently used applications: MTP cable and multi-fiber termination push-on cassettes. They are the best choices for providing a simple, cost-effective, and structured cabling system.

Figure 3: MTP Solutions

Multi-fiber termination push-on cables usually consist of the multi-fiber termination push-on connectors and the fiber optic cables. Sometimes, the LC connectors are used, which we will expound in the following part. As for fiber cables, they are typically used in OS2, OM3 or OM4. With different applications, the multi-fiber termination push-on cable can be classified into multi-fiber termination push-on trunk cable and multi-fiber termination push-on harness cable.

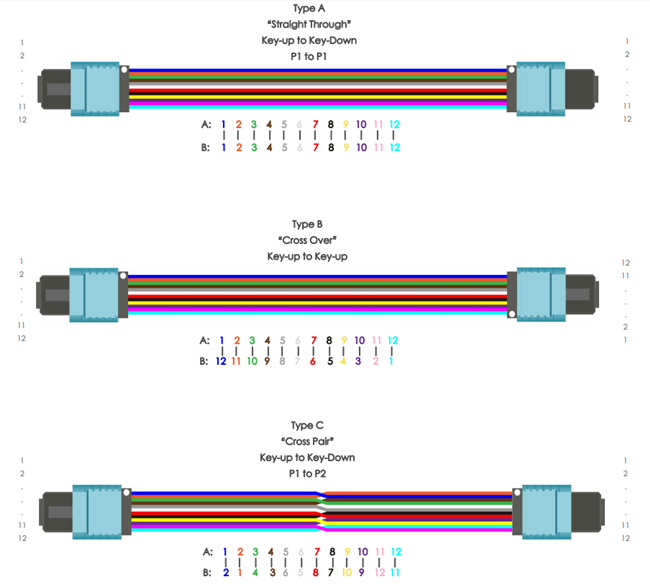

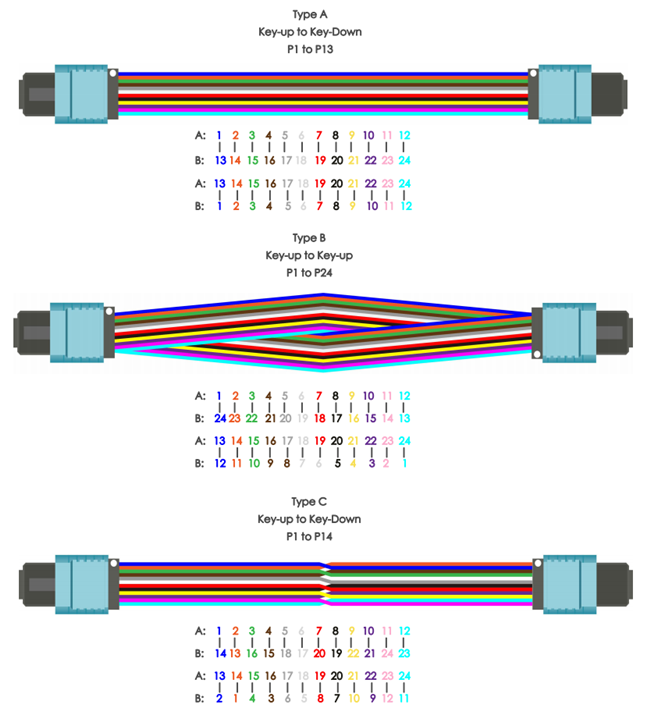

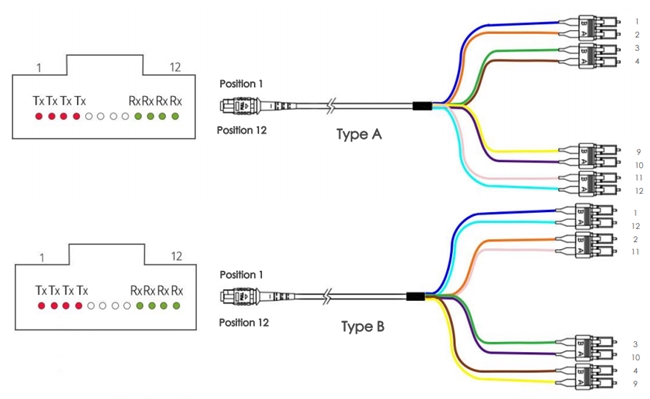

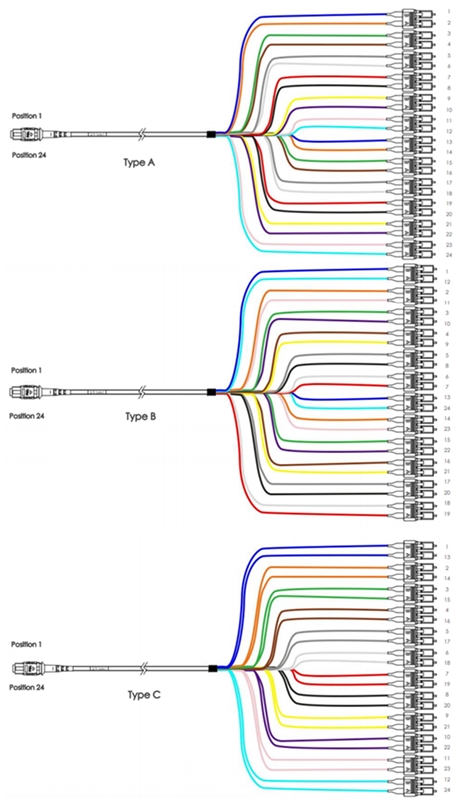

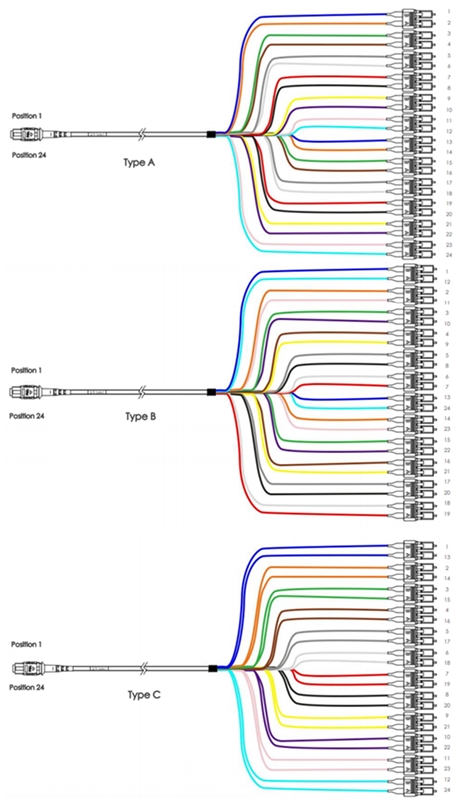

Serving as a permanent link, the trunk cable is designed to connect multi-fiber termination push-on or multi-fiber push on modules to each other. It’s available in 12, 24, 48 and 72 fibers. For the ends, the cable is commonly found to be terminated with 12-fiber or 24-fiber multi-fiber termination push-on or multi-fiber push on connectors. When it comes with the polarity of the patch cord, there are three different types (type A, B, and C), which is defined in the TIA standard. In the following figures, the three different connectivity methods for 12-fiber and 24-fiber MTP/MPO trunk cable are showed respectively.

Figure 4: 12-Fiber Multi-fiber Termination Push-on Trunk Cable

Figure 5: 24-Fiber Multi-fiber Termination Push-on Trunk Cable

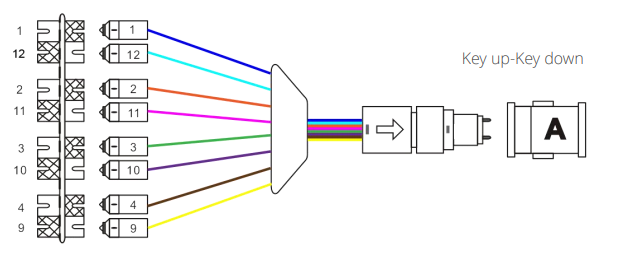

Multi-fiber termination push-on harness cable is used to provide a transition from multifiber cables to individual fibers or duplex connectors. For instance, 8 fibers 12 strands MTP-LC breakout cable has eight LC fiber connectors and a multi-fiber termination push-on connector. According to data of FS.COM, the 8-fiber and 24-fiber MTP to LC breakout cables are the best-selling multi-fiber termination push-on connector harness cables. For the polarity, the 8-fiber multi-fiber termination push-on connector breakout patch cord has two types (Type A and Type B); while the 24-fiber harness cable has three types (Type A, Type B, and Type C). For details, please refer to the following figures.

Figure 6: 12-Fiber Multi-fiber Termination Push-on Harness Cable

Figure 7: 24-Fiber Multi-fiber Termination Push-on Harness Cable

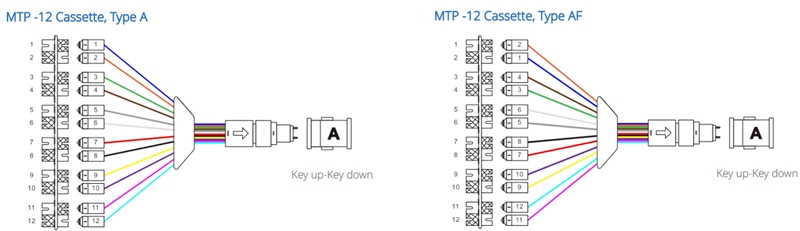

MTP-cassette is a kind of pre-terminated cassette module. It enables the “transition” from ribbon cables terminated with multi-fiber termination push-on connector connectors to the LC or SC interface on the transceiver terminal equipment. Conventionally, the multi-fiber termination push-on connector cassette is loaded with 8, 12 or 24 fibers and have LC or SC adapters on the front side and multi-fiber termination push-on connector at the rear. Nowadays, the three most widely used cassettes are MTP-8, MTP-12, and MTP-24 cassettes, or also known as Base-8, Base-12, and Base-24 multi-fiber termination push-on cassettes. For MTP-8 cassette, it is only available in Type A. While multi-fiber termination push-on-12 and multi-fiber termination push-on-24 cassettes both come with Type A and Type AF. For their polarity details, please refer to the following figures.

Figure 8: Multi-fiber Termination Push-on-8 Cassette

Figure 9: Multi-fiber Termination Push-on-12 Cassette

Figure 10: Multi-fiber Termination Push-on-24 Cassette

Summary

In this post, we make an overview of MTP, including what the multi-fiber termination push-on and multi-fiber push on, and what their the polarities are. Then we share three types of multi-fiber termination push-on solutions for high-density networking: MTP trunk cable, MTP harness cable, and MTP cassette.