FTTH (Fiber to the Home) network connects a large number of end users to a central point known as an access node to provide the application and services of high speed. The links between end users and access node are achieved largely by fiber optic cables. Loose buffer cables and tight buffer cables are commonly used to transmit signals with high speed, which are capable of surviving outdoor environment or indoor environment. However, to accomplish the whole transmission link, loose buffer cables for outdoor application should be connected with the tight buffer cables for indoor application. The splicing and termination of these fiber optic cables come as one of the largest link items in a FTTH system installation budget.

Is there a cost-effective and time-saving solution by using a single type of cable that can survive both indoor and outdoor environment in FTTH network? The answer is YES. Tight buffer indoor/outdoor cable is such a cable. It is a specially designed tight buffer cable which can answer the market call for a single type cable surviving both indoor and outdoor environment. To understand why it is a better choice for FTTH installation, the construction and comparison of loose tube cable and tight buffer cable will be introduced firstly.

The “buffer” previously mentioned in “loose buffered” and “tight buffer” is actually a basic component of fiber optic cable and the first layer used to define the type of cable construction. A typical fiber optic cable consists of the optical fiber, buffer, strength members and an outer protective jacket (as showed in the following picture). The buffer literally is used to provide protection and some tensile strength, which are useful when pulling the cable to install it or when it must hang between two suspension points.

Loose buffer cable consists of a buffer layer that has an inner diameter much larger than the diameter of the fiber (showed in the following picture). Thus, the cable will be subject to temperature extremes that cause expansion or contraction. That’s why loose buffered cable are usually used outdoor. The loose buffer cables designed for FTTH outdoor application are usually loose-tube gel-filled cables (LTGF cable). This type of cable is filled with a gel that displaces or blocks water and prevents it from penetrating or getting into the cable.

Tight buffer cable using a buffer attached to the fiber coating is generally smaller in diameter than loose buffer cable (showed in the following picture). The minimum bend radius of a tight buffer cable is typically smaller than a comparable loose buffer cable. Thus tight buffer cable is usually used in indoor application.

Tight buffered indoor/outdoor cable with properly designed and manufactured can meet both indoor and outdoor application requirements. It?combines the design requirements of traditional indoor cable and adds moisture protection and sunlight-resistant function to meet the standards for outdoor use. Tight buffered indoor/outdoor cable?also meets one or more of the code requirements for flame-spread resistance and smoke generation.

The structure and performance advantages of tight buffer indoor/outdoor cable have been introduced above. How about the other advantages? The following will explain why tight buffered indoor/outdoor cable is a better FTTH cable solution from the aspects of cost and reliability.

Using the traditional choice of LTGF cables as the outdoor cable, there would be a conversion from one fiber type from another type, which includes prep work on the fiber, the need for splice tray, the routing of fibers in the tray, and other similar detail. Before termination and splicing, the gel of LTGF cable must be cleaned and the breakout point of the main cable must be blocked by some method to prevent oozing of the cable gel. In addition, this cable type must normally be terminated or spliced close to the cable entryway of a building to switch to indoor cable, as it generally incompatible with indoor fiber codes. This time consuming and labor intensive process adds hidden costs to install the LTGF cables.

However, using only tight buffer indoor/outdoor cable for FTTH is much more convenient and cost-effective. A tight-buffered indoor/outdoor cable can be used throughout the link, requiring no transitions at the building entryway. Tight buffer indoor/outdoor cable requires less care to avoid damaging fibers when stripping back the cable. The termination and splicing of these cables are easier than that of LTGF cables.

An important reason why choose tight-buffered indoor/outdoor cable for FTTH cable installation is the reliability of the overall system. Splicing are the weakest point in a FTTH network. With splicing, the bare fiber ends are open to dust, dirt, water, vapor, and handing which might reduce the fiber strength and increase brittleness. Choosing loose tube outdoor cable for FTTH, there will be splices after the conversion from one cable type to another type. The splices inside a building may be held in a cabinet that is open to the air, which might decrease the reliability of the FTTH network. Using the tight buffer indoor/outdoor cable could eliminate splicing and improve the installation reliability greatly.

In conclusion, the benefits of tight buffer indoor/outdoor cable are clear. The installer can run a single cable type and remove a transition point between the outside plant and the inside plant, which decrease FTTH installation cost and time effectively. At the same time, the reliability of the overall FTTH network can be increased greatly.

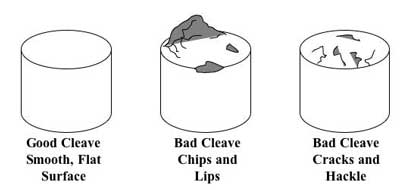

Scribe – Except the cleaver, there is another tool for cleaving which is typically used to remove excess fiber from the end of a connector before polishing. Scribe is a simple hand tool with a hard, sharp tip (generally made of carbide or diamond), that is used to scratch the fiber manually (some scribes are with pen-style shapes). Then the operator pulls the fiber to break it. However, it is less predictable than a cleaver because both the scribing and breaking process are under manual control. Nonetheless, scribe can produce adequate results for polishing so that it is still used today.

Scribe – Except the cleaver, there is another tool for cleaving which is typically used to remove excess fiber from the end of a connector before polishing. Scribe is a simple hand tool with a hard, sharp tip (generally made of carbide or diamond), that is used to scratch the fiber manually (some scribes are with pen-style shapes). Then the operator pulls the fiber to break it. However, it is less predictable than a cleaver because both the scribing and breaking process are under manual control. Nonetheless, scribe can produce adequate results for polishing so that it is still used today.