Optical fibers with fiber counts ranging from 2 to 144 counts or more are usually coated together inside a single strand of fiber optic cable for better protection and cabling. Multi-fiber optic cables are usually required to pass a lot of distribution points. And each individual optical fiber should connect only one specific optical interface via splicing or terminating by connectors. Thus, fiber optic cables used for distribution should be durable and easy to be terminated. Tight buffered fiber distribution cables, which meet these demands, are widely used in today’s indoor and outdoor applications, like data center and FTTH projects. This post will introduce tight buffered fiber distribution cables.

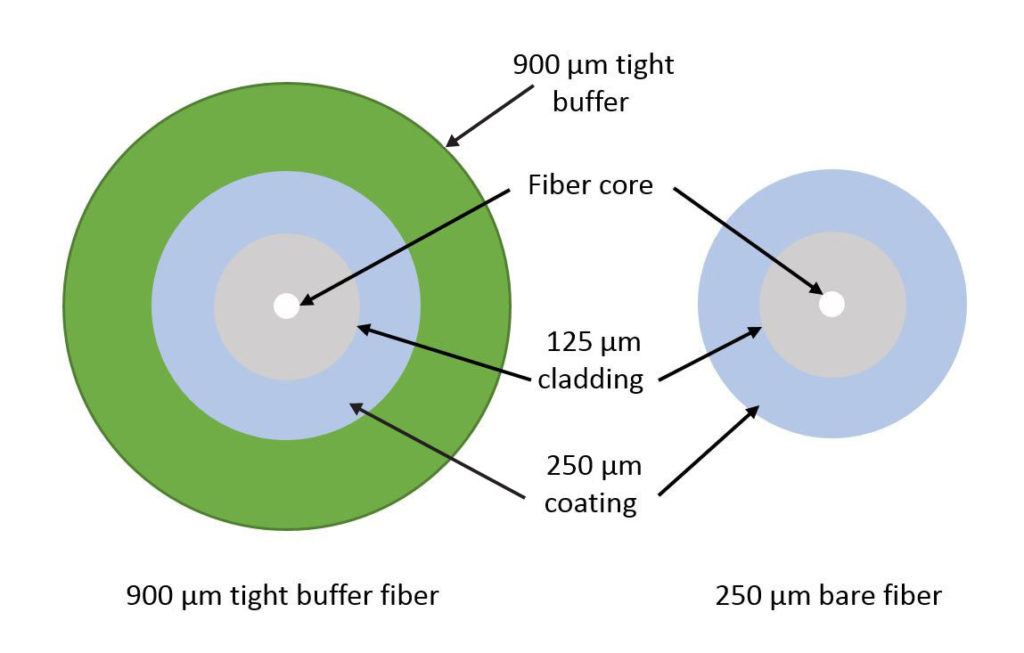

Most of tight buffered fiber distribution cables are designed with 900um tight buffered fibers. This is decided by its applications. As the above mentioned, the distribution cable should be durable and easy to be terminated. The following picture shows the difference between 250um bare fiber and 900um tight buffered fiber. They are alike, but the tight buffered fiber has an additional buffer layer. Compared with bare fibers, 900um tight buffered fibers can provide better protection for the fiber cores. 900um tight buffered fibers are easy to be stripped for splicing and termination. In addition, tight buffered fiber cables are usually small in package and flexible during cabling. These are the main reasons why a lot of fiber optic distribution cables use tight buffered design.

900nm tight buffered distribution fiber cables also come in a variety of types. Tight buffered distribution fiber cables used for different environments and applications might have different fiber types, outer jackets and cable structures. The following will introduce several tight buffered distribution fiber cables for your reference.

Indoor Tight Buffered Distribution Fiber Cable

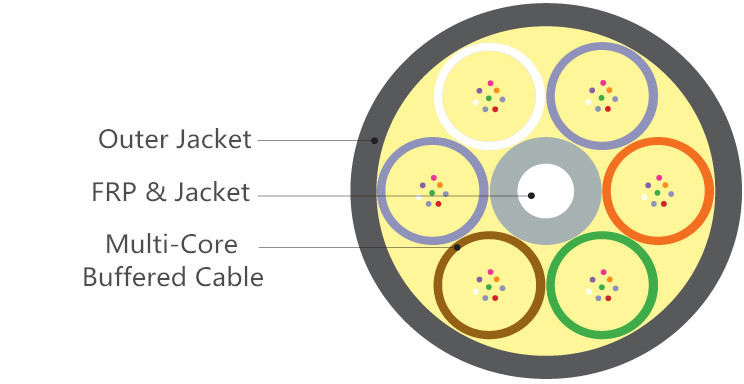

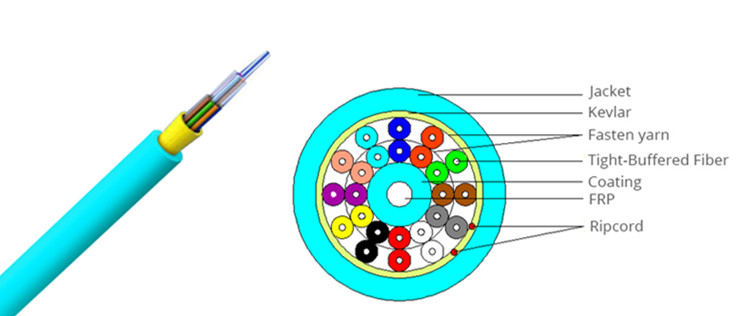

Tight buffered distribution fiber cables used for indoor applications are usually used for intra building backbones and routing between telecommunication rooms. Large tight buffered fiber cable with fiber counts more than 36 fibers generally has “sub-unit” (unitized) design (shown in the above). While smaller tight buffered distribution cables, with fiber counts of 6, 12 or 24, usually have “single-jacket” (non-unitized) designs, which are more flexible in cabling and have much smaller packages and cost advantages. The lower count tight buffered distribution fiber cables with color coded 12 fibers and 24 fibers are very popular. The following picture shows a 24-fiber indoor tight buffered distribution fiber cable with single-jacket design.

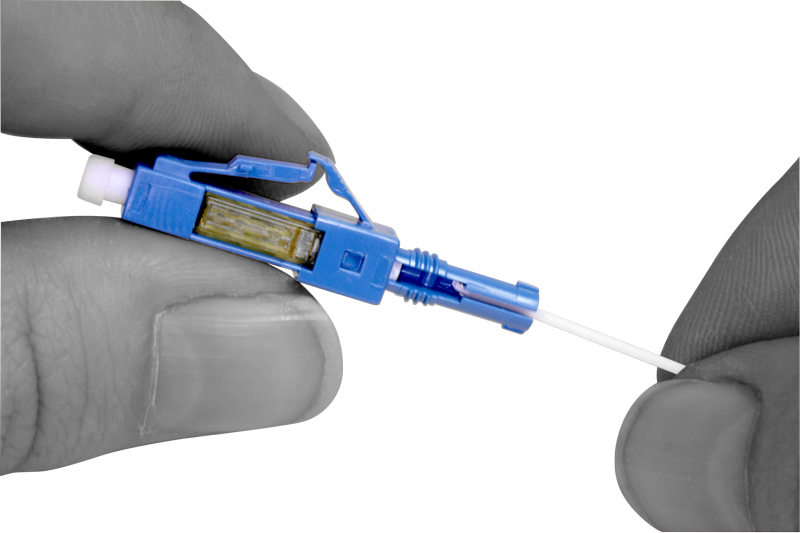

During practical use, these 6, 12 or 24-fiber indoor tight buffered distribution fiber cables can be spliced with other fibers or be terminated with fiber optic connectors. And they can be made into multi-fiber optic pigtails or fiber patch cable after terminated with fiber optic connector on one end or two end. The color coded fibers can also ease fiber cabling.

Indoor/Outdoor Armored Tight Buffered Distrib ution Fiber Cable

ution Fiber Cable

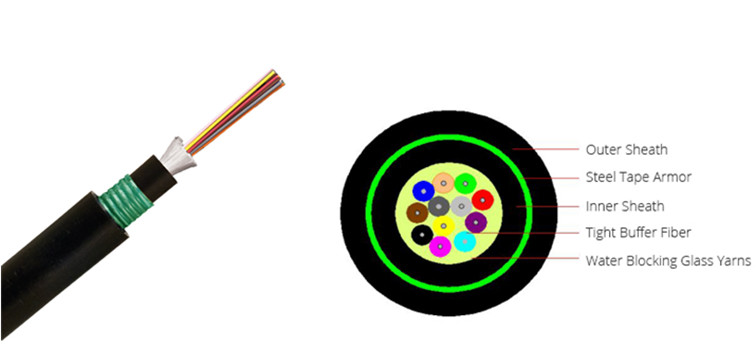

Although tight buffered distribution fiber cables are usually used for indoor applications, there is still a place for them in outdoor applications after added with a layer of metal armored tube inside the cable. Armored fiber cables are durable, rodent-proof, water proof and can be directly buried underground during installation, which saves a lot of time and money.

Here we strongly recommend a low fiber count armored tight buffered distribution fiber cable which can be used for both indoor and outdoor applications (show in the above picture). This low fiber count armored tight buffered cable has a single-jacket design with a steel armored tape inside the cable. It can be used for both backbone cabling and horizontal cabling in indoor environments. And it can also be used for direct buried applications and aerial application in outdoor environments.

During the purchasing of fiber optic cables, one of the most important thing is the shipment of fiber cables. Many bulk fiber cables are transmitted via shipping, which might take a long time. Now FS.COM customers in the USA can enjoy same day shipping for tight buffered distribution fiber cables for both indoor and outdoor applications. Details are shown in the following table. Kindly contact sales@fs.com for more details, if you are interested.

| Part No. | Description |

| 31909 | 12 Fibers OM3 Plenum, FRP Strength Member, Non-unitized, Tight-Buffered Distribution Indoor Fiber Optical Cable GJPFJV |

| 31922 | 12 Fibers OM4 Plenum, FRP Strength Member, Non-unitized, Tight-Buffered Distribution Indoor Fiber Optical Cable GJPFJV |

| 31866 | 24 Fibers OM4 Riser, FRP Strength Member, Non-unitized, Tight-Buffered Distribution Indoor Fiber Optical Cable GJPFJV |

| 51308 | 24 Fibers OS2, LSZH, Single-Armored Double-Jacket, Tight-Buffered Distribution Waterproof Indoor/Outdoor Cable GJFZY53 |

Related Article: Tight-Buffered Fiber Distribution Cable for Indoor and Outdoor Use