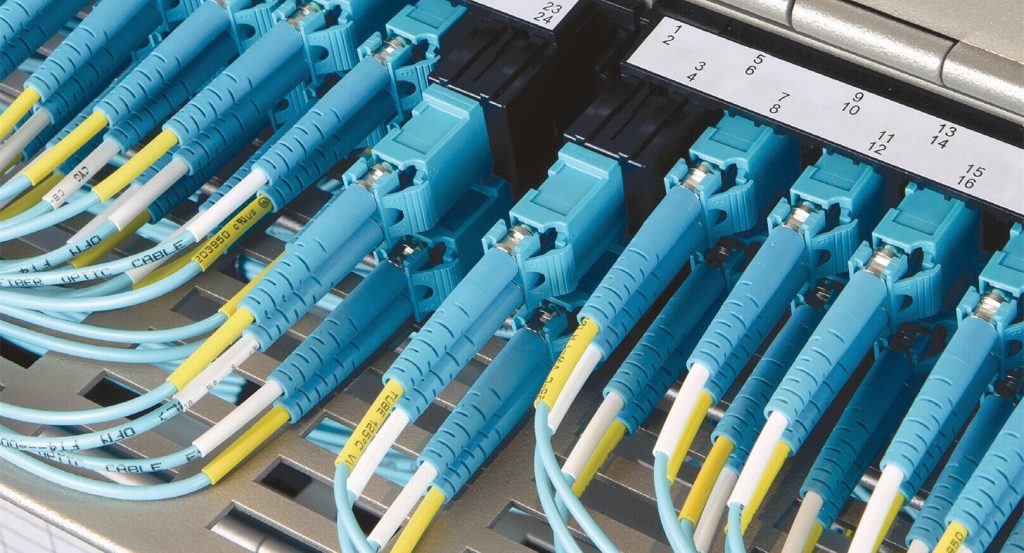

Cable management is a critical part of network cabling systems that require a large number of moves, adds and changes. The improper cable management may result in cable damage or cause transmission errors and performance issues as well as system downtime. In a horizontal manager system, the cable management for rack is important in telecommunications rooms for leased office space, brokerages and trading houses where the workstations will move or add additional ports frequently. This post will analyze why the horizontal rack cable management is important and offers FS horizontal cable management solutions for rack.

Why Is Proper Horizontal Rack Cable Management Important?

- Poorly routed cables can lead to an assortment of problems over time. Jumbled cables would increase the risk of cables to be tangled up, and a possibility of interruption when reconnecting the cables.

- The rack cable management is directly related to hardware safety. All equipment running on the server rack is going to generate heat, so organizing a rack with a conception involving space will help promote the airflow and hardware management.

- Cable labels in a proper horizontal rack cable management can save a lot of time on troubleshooting. Just imagine how difficult it would be to trace a cable through that mess.

- If rack cables were unorganized, a technician would spend hours tracing wires when something goes wrong. In most circumstances, we can’t afford to stay offline while a technician unravels a tangled nest of cables. Thus a proper horizontal cable management makes it easy for the technician to identify and access where goes wrong and fix it in far less time.

Horizontal Cable Management for Rack: Where to Start with?

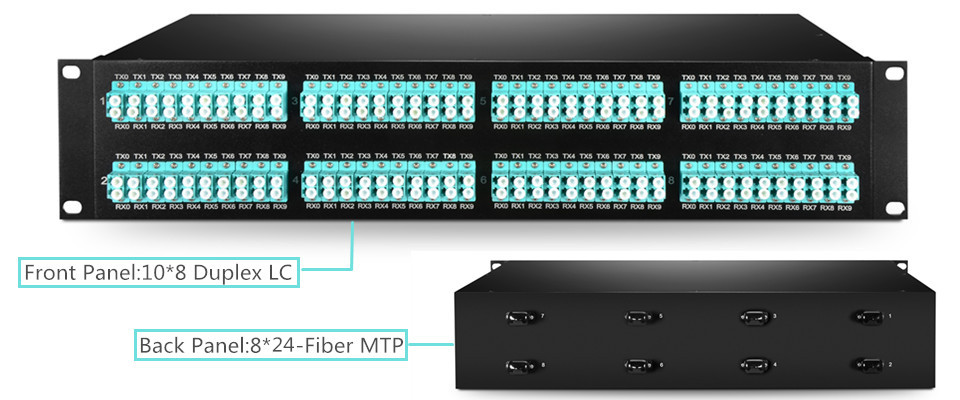

Horizontal cable management system is often installed within racks or cabinets to manage cables on front racks and draw cables away from equipment neatly. The rack space of a horizontal cable management infrastructure is typically 1U or 2U high. The following part gives the FS plastic & metal horizontal fiber patch panel, cable managers, lacer panels to promote a proper cable management in your horizontal network cabling systems.

Horizontal rackmount fiber patch panels help to organize cables and eliminate cable stress for your rack enclosure cabinet. FS offers 1U 19’’ blank rackmount fiber patch panels with plastic D-rings on the cable management panel and lacing bar. These rackmount fiber patch panels can be used to organize cables for fiber optic adapters, fiber enclosures, Ethernet switches, WDM chassis, etc.

| ID | 59576 | 72910 |

| FS P/N | FHD-1U-CMP300 | FHD-FPP5DRL |

| Fiber Counts | Max.96 Fibers | Max.96 Fibers |

| Material | Metal (SPCC) | Metal+Plastic |

| No. of D-rings | 5 (Metal) | 5 (Plastic) |

| Detachability | Yes (with Screws and Tools) | Yes (Without Tool) |

Horizontal cable managers with finger duct and brush strip allow neat and proper routing of the patch cables from equipment in racks and protect cables from damage. Fixed inset fingers on the front and back allow easier access to the ports for moves, adds, and changes. And the brush strip horizontal cable manager is constructed of high-quality steel with high-density nylon bristles, which can promote proper airflow through the rack and meet the demand for front-to-back cable runs.

| ID | 29038 | 29040 | 29039 | 68690 | 29033 |

| FS P/N | CMH-SFD1U | CMH-DFD1U | CMH-SFD2U | CMH-4DRB1U | 1U-BR-CMP |

| Material | Plastic | Plastic | Plastic | Metal (SPCC) | Metal (SPCC) |

| Style | Finger Duct | Finger Duct | Finger Duct | Brush Strip & D-rings | Brush Strip |

| Cable Capacity | 44(Cat6) | 44(Cat6) | 100(Cat6) | 100(Cat6) | – |

Horizontal lacer panels are efficient tools for rack or enclosure cabling. These D-rings on the lacer panel are essential to avoid cable strain and prevent damage to the ports on your rack-mount equipment. The five rotating D-rings can be easily assembled or disassembled manually according to your needs.

| ID | 64457 | 72911 |

| FS P/N | FHD-1U-CMP100 | FHD-CMP5DR |

| Style | D Rings | Plastic D Rings |

| Number of Rings | 5 | 5 |

| Material | Metal (SPCC) | Metal+Plastic |

| Detachability | Yes | Yes |

Conclusion

This post provides users with a horizontal cable management solution that simplifies cable routing in a finished professional appearance. With proper and efficient horizontal cable management tools, cable spaghetti is not a problem anymore. You can just have a peace of mind and reap the great benefits of sound cable management. FS horizontal cable management tools provide an efficient way to manage high performance copper, fiber optic, or coaxial cables on any 1U or 2U rack. For more details, please kindly visit www.fs.com.

Related Article: FS.COM 1U Cable Management Solutions Guide

Related Article: Selecting the Right Horizontal Cable Manager