Deploying more fiber optic cable is just the first step to meet the high-bandwidth requirements, strong management over the fiber optic cable is a basic requirement for a successful fiber optic network infrastructure. Fiber patch cable might be the weakest link in optical network infrastructures. To deliver and guarantee and optimal network performance, patch cable management is critical. In addition, cable management of optical fiber can lower operation cost & time and increases the reliability and flexibility of network operation and maintenance. This post will offer the critical elements that should be noted during patch cable management, as well as tips for fiber patch cable management.

To get a flexible and well-organized patch cable management, the factors that affect the performance of the fiber optic patch cable should be introduced first. Here are four key elements that should be considered during patch cable management.

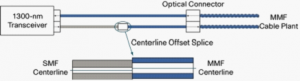

Unlike copper, fiber optic made of glass is much fragile and need more protection and attention during the operation and management. Thus, the fiber’s bend radius will impact its reliability and performance. If a fiber cable is bent excessively, the optical signal within the cable may refract and escape through the fiber cladding which will cause a loss of signal strength and is known as bend loss. What’s more, bending, especially during the installation and pulling of fiber optic patch cable might also cause micro cracks and damage the fiber permanently. Generally, there are two basic types of bends in fiber, which are microbends and macrobends as shown in the following picture. The macrobends are larger than microbends.

What should be noted is that bend radius might not be seen during the initial installation of fiber patch cable. This is because the number of patch cables routed to the optical distribution ODF is usually small. However, when more patch cords are added on the top of installed patch cables in the future the problems will come across (shown in the following picture). A fiber patch cable that working fine for years might suddenly have an increased level of attenuation, as well as a potentially shorter service life.

Patch cable path is an aspect closely related to bend radius that can affect the performance and maintenance of the patch cable. The path of the patch cable should be clearly defined and easy to follow. Improper cable routing can cause increased congestion in the termination panel, increasing the possibility of bend radius violations and long-term failure. However, the well-managed patch cable path ensures that bend radius requirements are maintained at all points and makes accessing individual patch cable easier, quicker and safer. What should be mentioned is that the well-organized fiber patch cords can help to decrease operating costs and the time required to turn-up or restore service.

The third aspect is the accessibility of the installed patch cable. If the installed patch cable is easy to be accessed, the maintenance and operation would be quick without inducing a macrobend on an adjacent fiber, and it can also offer proper bend radius protection. Accessibility is critical during network reconfiguration operations and directly impacts operation costs and network reliability.

Patch cables routed between pieces of equipment can largely affect network reliability. Without proper protection, they would be easy to be damaged by technicians and equipment accidentally. Thus, physical protection of the installed patch cords is very important.

According to the mentioned aspects that can affect the performance and maintenance of the fiber optic patch cable, here offers several tips that can help to increase the performance of patch cords, as well as the reliability and flexibility of patch cable management.

Tip 1: Pay attention to the bend radius of the patch cable. Generally, for 1.6mm and 3.0mm cords, the minimum un-loaded bend radius is 3.5 cm, and the minimum bend radius of MPO patch cable is ten times the cord diameter.

Tip 2: Never pull or stress the patch cords (shown in the following figure). During the patching process, excessive force can stress fiber patch cables and connectors attached to them, thus reducing their performance. There might be something wrong if you need to use force in pulling a cord.

Tip 3: Routing cords through cable pathways. If the existing cord is the right length, it may be possible to re-use it. If this is the case, remove the cord completely and re-run it in through the cable pathways. This is the only sure way to ensure there are no tangles, kinks or strains in the cord. For efficient routing, find the best path between the ports to be connected. Avoid routing cords through troughs and guides that are already congested.

Tip 4: Bundling and tying cords give the panel a neat appearance but tight bundling increases the risk of pinching (as shown in the following figure). Do not tighten cable ties beyond the point where individual cords can rotate freely.

Tip 5: Labeling is necessary. Labeling is the most important part of a System Administrator’s responsibilities. At any administration point in a cabling infrastructure, including patch panel, accurate labels are essential. These will identify pair modularity and tell technicians where the other end of the cable is terminated.

Tip 6: Inspect fiber cords for physical damage including stress marks from sharp bends on the sheath, or damage to connectors as shown in the following figure.

A strong and successful patch cable management which can increase the reliability and flexibility and decrease the cost of network operation and maintenance should provide bend radius protection, reasonable patch cable path, easy accessibility of patch cable and physical protection. When the four mentioned aspects are satisfied, there is already half the success of strong patch cable management.

Source: http://www.fs.com/blog/fiber-patch-cable-management.html