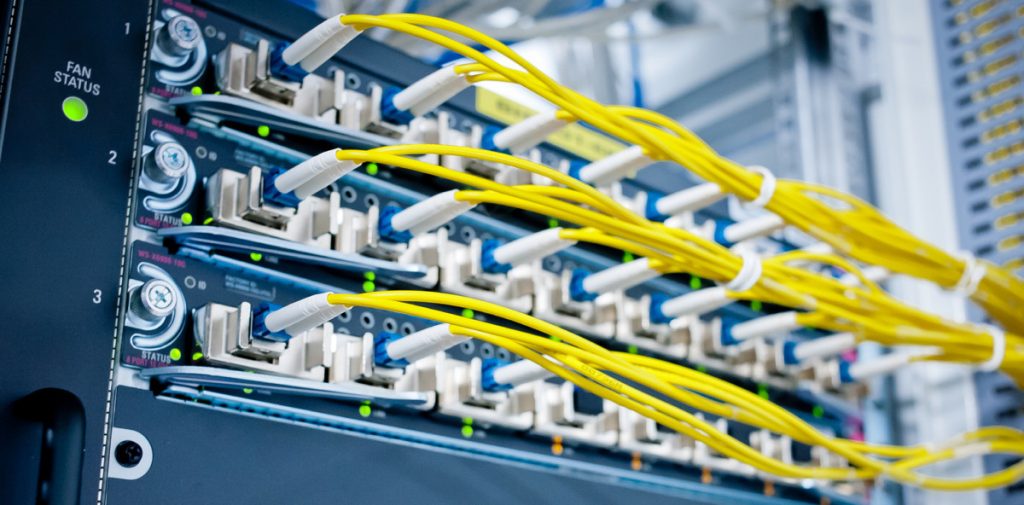

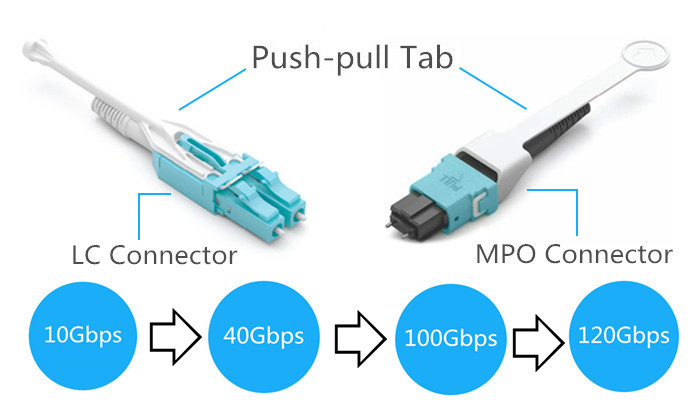

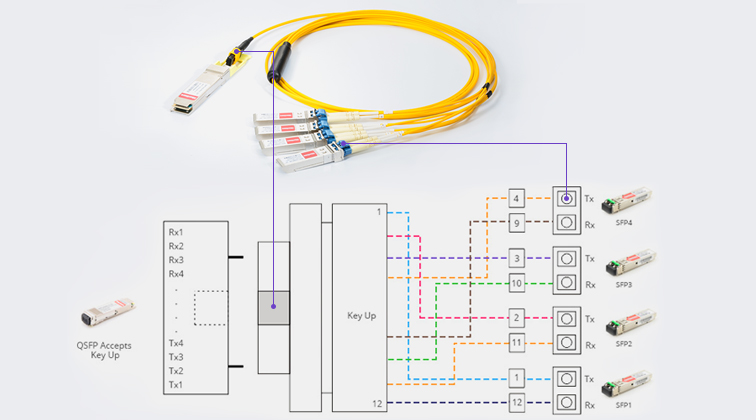

LC-LC patch cable has already become the main force of high density cabling network infrastructure. To future increase the profits of LC-LC fiber patch cable, manufactures has invented LC-LC patch cables of different features to meet various requirements in data center and increase the network performance.

Data center is a place of thousands fiber links. The selection of fiber patch cables will directly affect the network performance. More and more data centers choose to select fiber patch cable of high performance. Generally, insertion loss and return loss of connectors terminated on patch cable and light loss of optical fiber used for fiber patch cable are three most basic factors for fiber patch cable selection. To satisfy the increasing demands for higher density and easier management in data center, the optimization of fiber patch cable has never stopped. The following introduces several popular LC-LC fiber patch cables which represent the trends of fiber patch cable that data center is asking for.

When a length of fiber patch cable is connected in network, optical light loss occurs at the optical fiber and the connectors terminated on it. There are different optical light losses, among which insertion loss at the connectors and bend loss in fiber optic cables are the two most commonly light losses that technicians are trying to overcome. Manufactures provides LC-LC fiber patch cables which can minimize these losses to the most.

Insertion loss refers to the fiber optic light loss caused when a fiber optic component insert into another one to form the fiber optic link. To provide low insertion loss patch cable, LC connectors terminated on the patch cable has been optimized. Standard LC-LC patch cable usually has an insertion loss less than 0.3 dB. However, for upgraded LC-LC patch cable, the insertion loss is usually lower than 0.2 dB. To decrease the bend loss, a type of bend insensitive fiber (BIF) has been used in fiber patch cable. With optimized LC connectors and bend insensitive fiber, LC-LC fiber patch cable could provide lower light loss during network transmission.

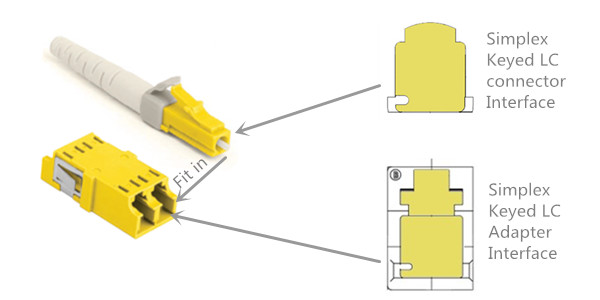

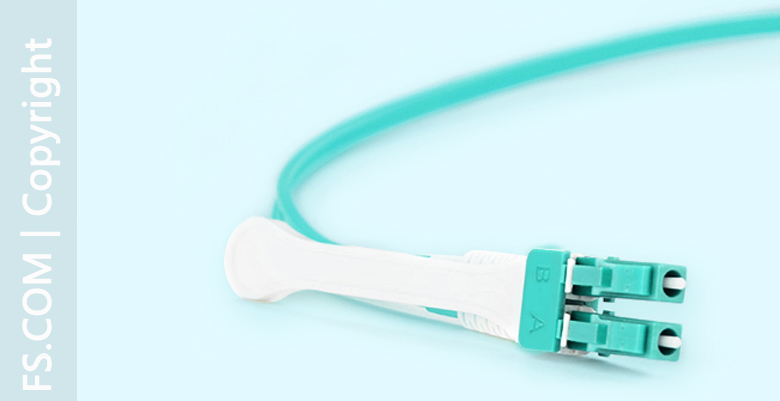

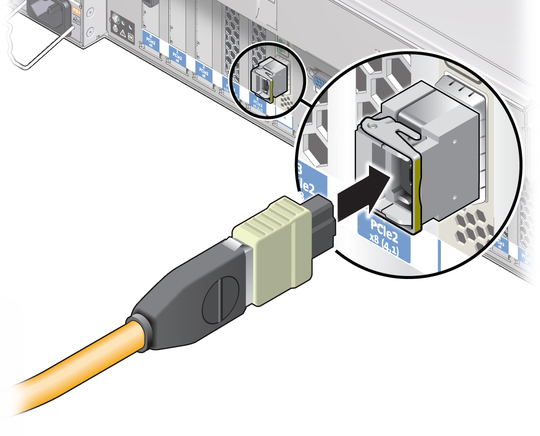

LC connector was invented for higher cabling density. standard duplex LC-LC fiber patch cable can provide much higher cabling density than other duplex fiber patch cables. To further increase cabling density in data center, the connectors and cable diameter of LC-LC patch cable are becoming smaller. Uniboot LC-LC patch cable is a typical example. This kind of fiber patch cable designed the two fibers of the duplex patch cable into a single cable. In adding the two connectors terminated at each end of the duplex patch cable share the same boot. With less using cable counts, uniboot patch cable can provide higher cabling density and better cooling environment in data center.

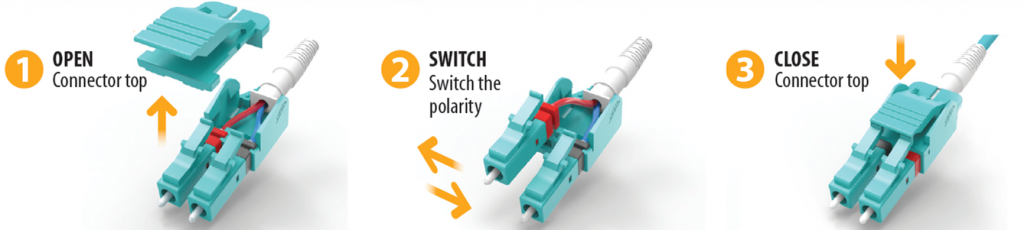

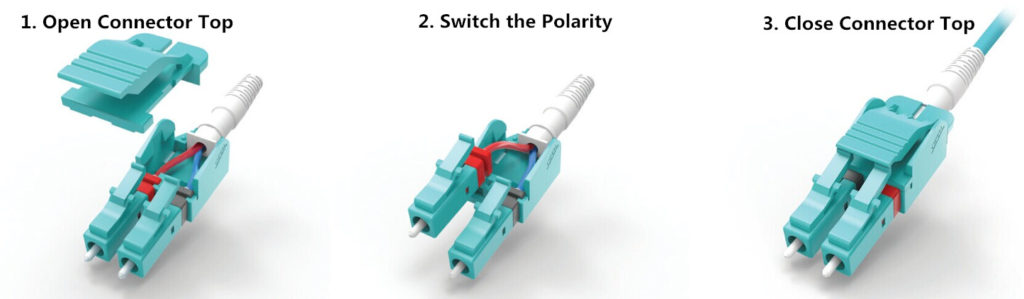

The development of patch cable won’t stop at low loss and high density. Making fiber patch cable easier-to-use is also important. Polarity of fiber patch cable matters a lot during installation of fiber patch cable, especially for duplex fiber patch cable and MTP patch cable. It is common to change the polarity of a duplex patch cable during deployment. Technicians might need tools to change the polarity of patch cable. However, a polarity switchable LC-LC patch cable can make things much easier. Without any tools you can polarity reversal could be really easy. The following picture shows the polarity reversal of a special designed LC-LC patch cable.

LC-LC patch cable has been designed into many different types. A high performance fiber patch cable should not only provide low insertion loss and bend loss, but also higher cabling density and easy-to-use features. This is also the trend of data center development.