PLC splitter is a simple passive component which plays an important role in the applications of technologies like GPON, EPON and BPON. It allows a strand of fiber optic signal being equivalently splitted into several strands of optical signal, which can support a single network interface to be shared by many subscribers. When selecting it, split ratios should always be considered. However, with the network cabling environment becoming increasingly complex, various PLC splitters with different package form factors are being invented. Now the package form factor of it is also a key factor to be considered. This post will introduce the most commonly used PLC splitters in different package form factors for your reference during selection.

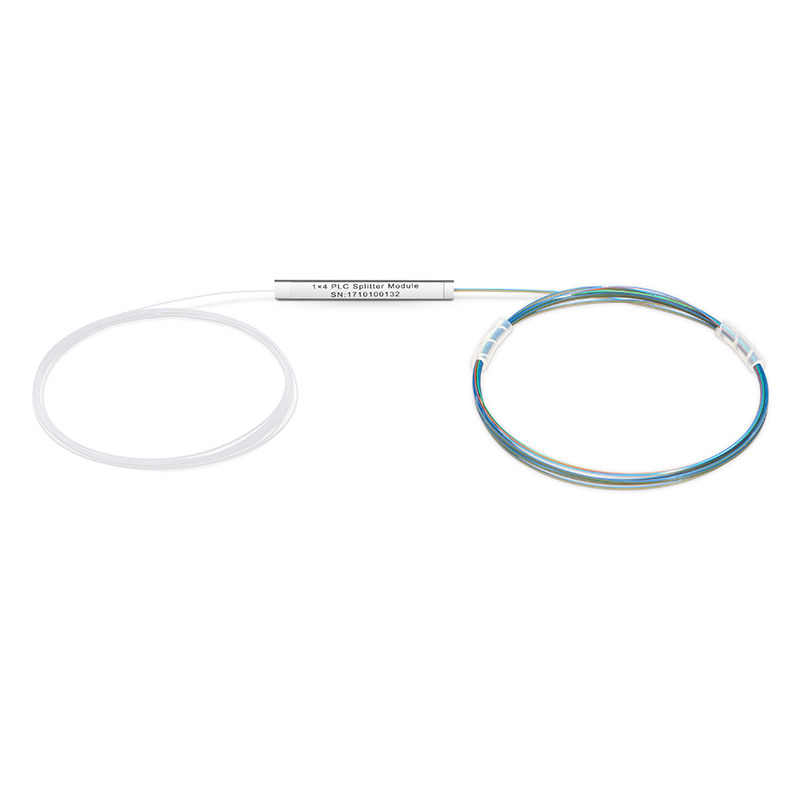

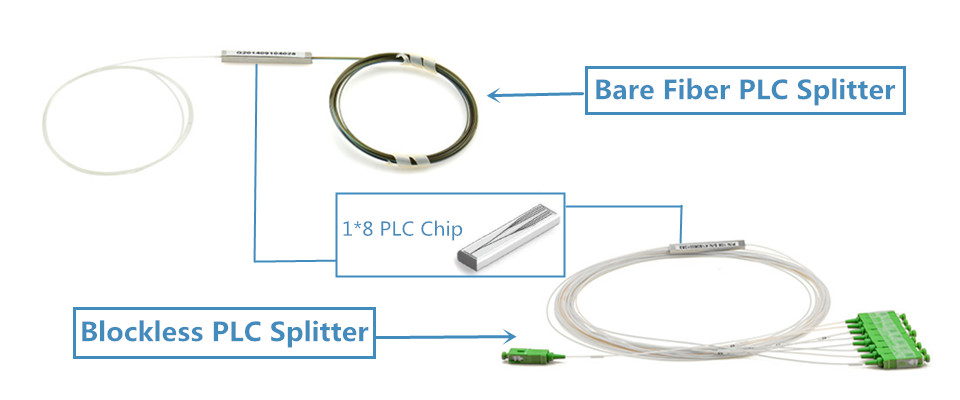

Bare fiber PLC splitter is commonly used in FTTx projects. It leaves bare fiber on all its ends. Thus, they can be spliced by network engineer freely according to the applications. Meanwhile, it requires the least space during cabling. They can be installed in fiber optic splicing closure easily to provide FTTH signal distribution.

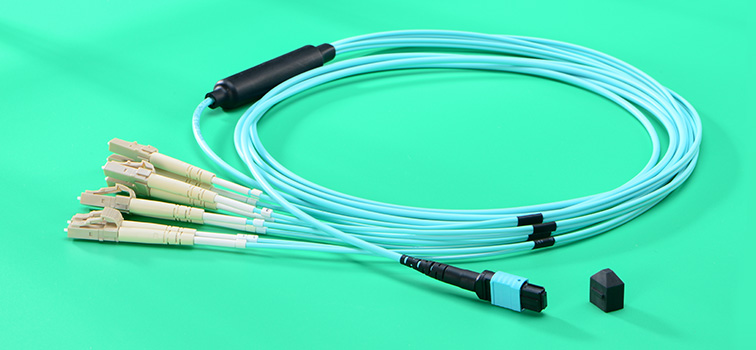

A blockless PLC splitter looks like a bare fiber splitter. The main differences are that the blockless one is usually terminated with fiber optic connectors and it uses a compact stainless tube package. It is also common that many bare fiber PLC splitters also use stainless tube package for the split chip.

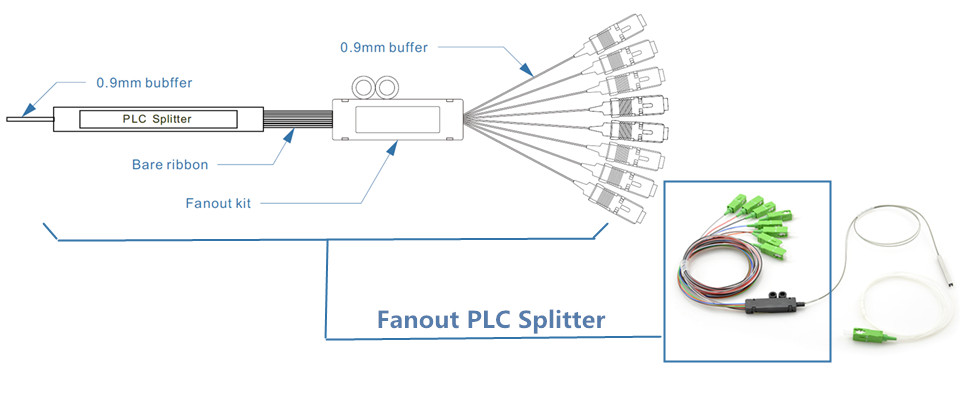

Fanout PLC splitter generally uses 0.9mm buffer fiber, added with a length of ribbon fiber terminated with fanout kit behind the PLC split chip. The splitter ratios of it also come in various types. The following picture shows a 1:8 fanout version which is terminated with SC/APC connectors.

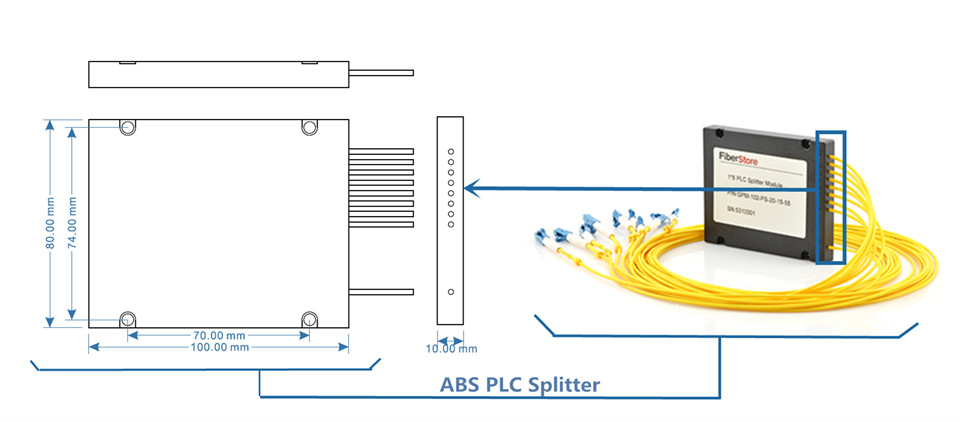

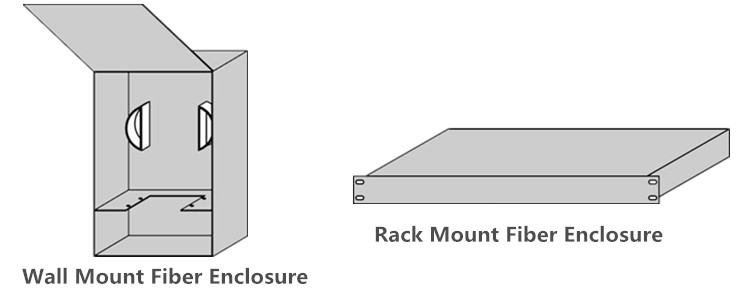

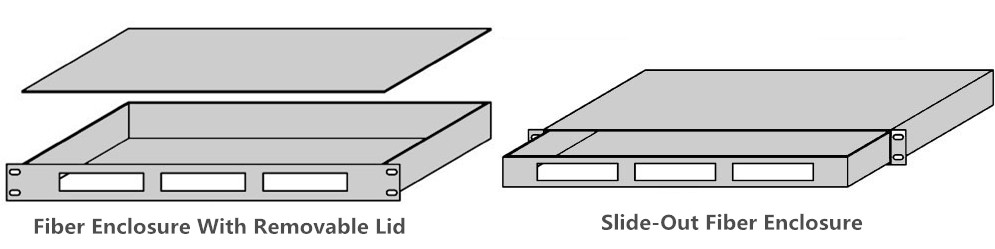

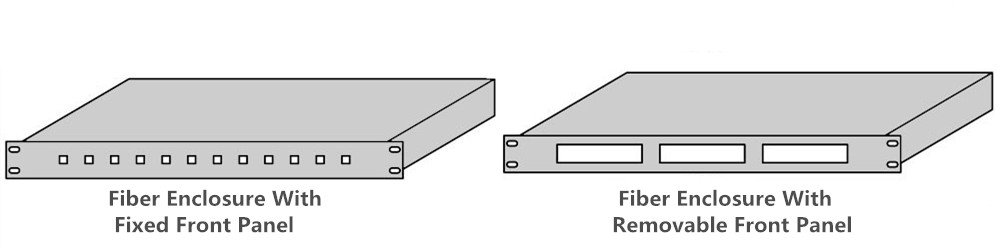

ABS PLC splitter uses ABS plastic box to holding the splitter chip. The inbound fibers and distribution fibers are arranged on the same plate of this ABS box, which can provide easier and more flexible cabling. Except providing reliable protection, it can also be installed in a variety of boxes or enclosures. It is very commonly to install a it in a standard 19-inch rack unit.

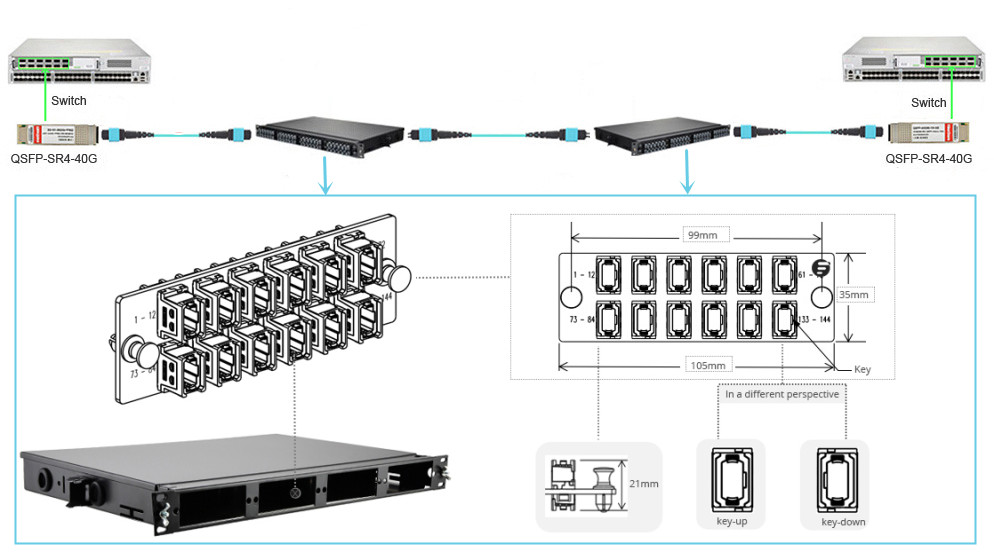

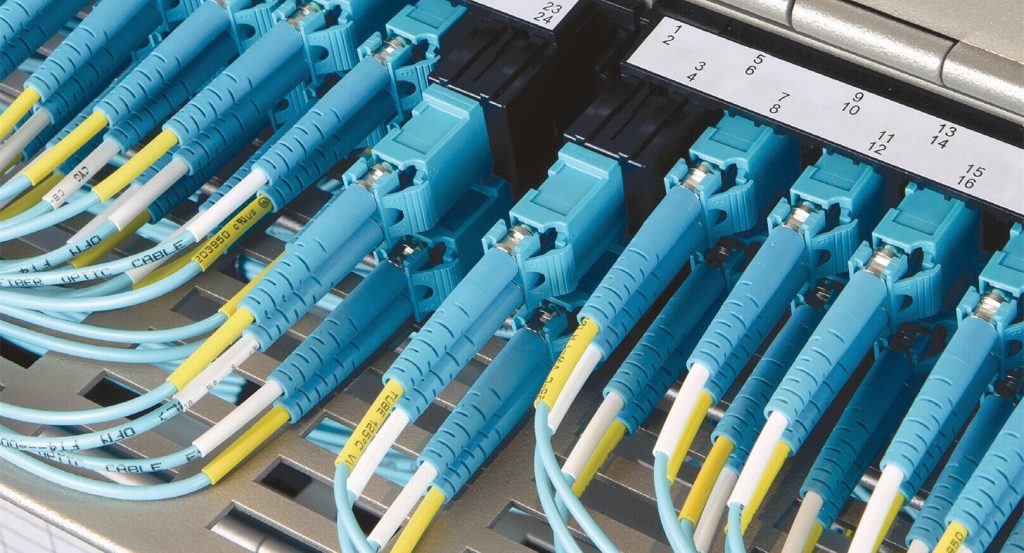

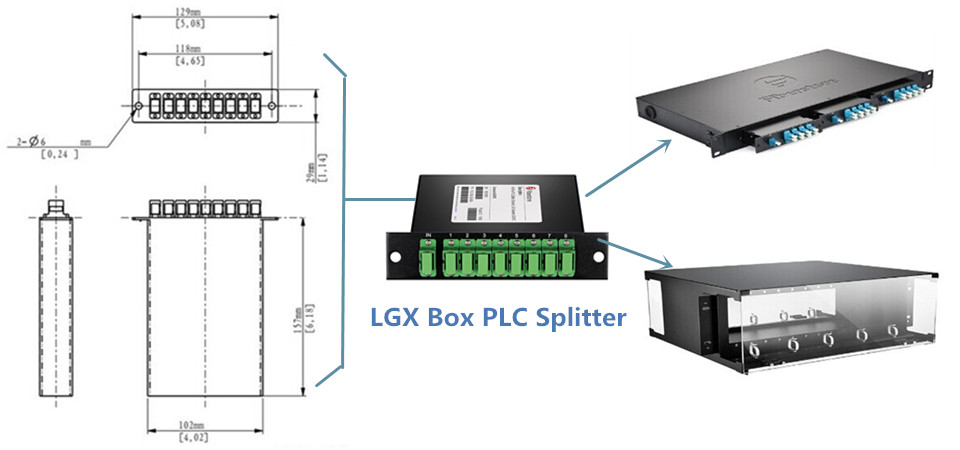

LGX Box PLC splitter looks like an MTP LGX cassette. It houses the whole splitter inside a metal box and leave fiber optic adapters for both inbound fibers and distribution fibers on its front panel. The LGX splitter can be used stand alone or be installed in the standard rack unit or fiber enclosures for better cabling.

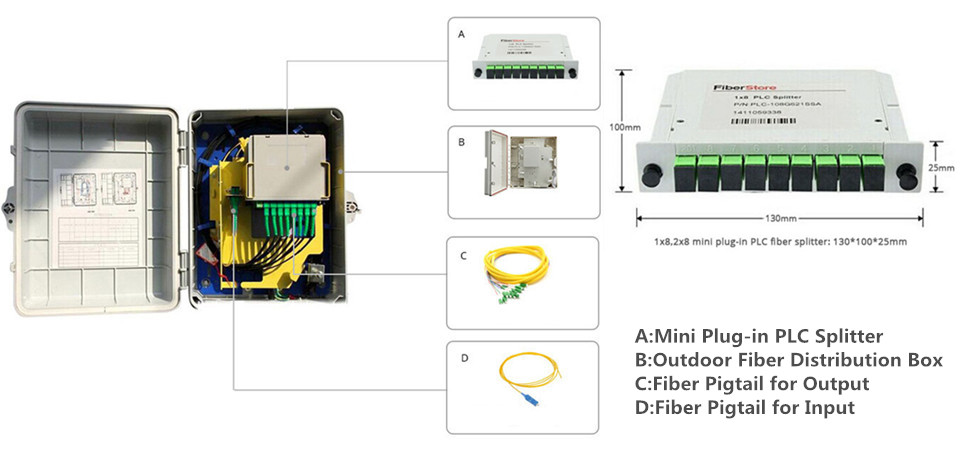

Mini plug-in PLC splitter is now widely used in FTTx project, especially at the distribution points near the end users of the FTTx networks. It provides fast installation and low space requirement helping to alert the deployment of FTTs projects. Fiber pigtails for input and output can be directly connected with this passive component easily.

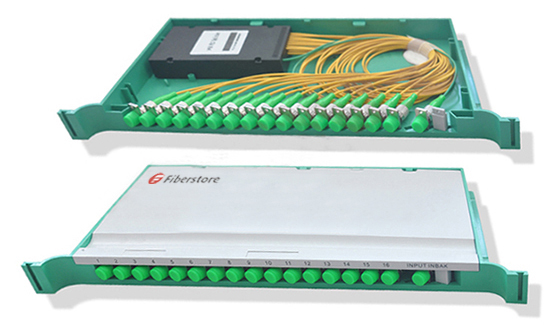

Tray type PLC splitter also uses a space saving package form factor for better cable management. However, it uses a international 19-inch design which can be deployed in ODF for compact cable management and signal distribution. With this design, the ports on tray type splitter are clearly marked, which can reduce the faults caused by wrong connections.

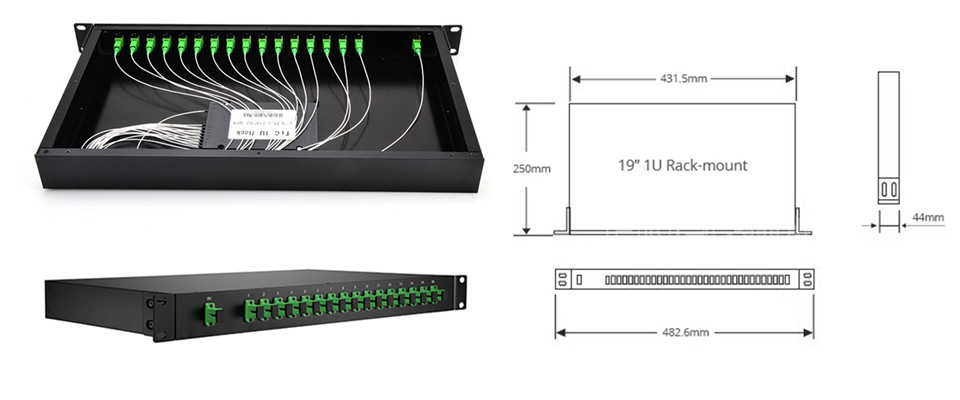

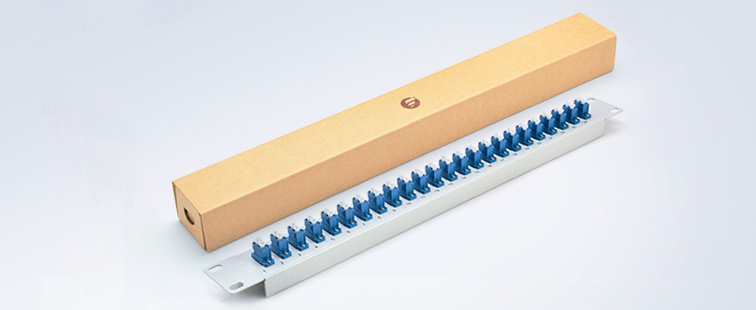

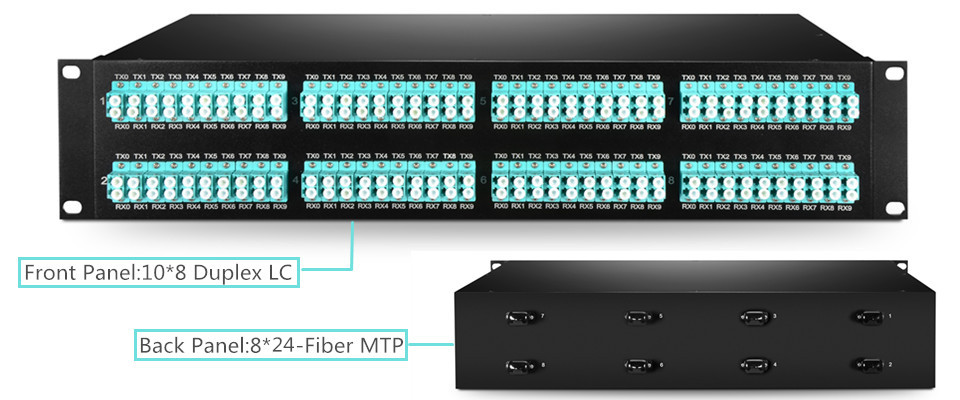

Rack mount PLC splitter is designed to meet the requirement of high cabling density for data centers or server room. It can be firmly installed on the data center or server racks. It is an ideal solution for high density cabling environment. FS.COM can provide PLC splitter ports up to 64 in 1U 19-inch rack. The following picture shows the details of a 1:8 rack mount one provided in FS.COM.

PLC splitter is a cost-effective passive optical component enabling a single network interface to be shared by two or more users. Selecting the right package form factor for it can help a lot during both the network deployment and maintaining. Most of the above mentioned splitters in different package form factors are all being provided in FS.COM. Customized ones are also available in FS.com. Kindly contact sales@fs.com for more details if you are interested.

Source:

How Many Fiber Optic Splitter Types Are There? – FS Community